What is lean methodology. The Lean methodology is an evolution of the Toyota Production System that the Japanese automaker implemented following World War II to improve the efficiency and flexibility of its manufacturing.

What Is Lean Management Definition Benefits

What Is Lean Management Definition Benefits

The methodology of Lean focuses on creating value at every level which builds overall value for your company and when done correctly can be transformational.

What is lean methodology. At its core adhering to the lean startup methodology is all about creating a sustainable business with minimal waste of both time and money. Many organizations from manufacturing to healthcare have successfully implemented Lean methodology. Two failed businesses in Ries own portfolio and The streamlined process of creating cars that was developed in Japan after World War II.

Precisely specify value by specific product identify the value stream for each product make value. Lean methodology originated with the Toyota Production System which revolutionized the manufacture of physical goods in the 1950s 60s and beyond. Though traditionally applied within the manufacturing sector principles of lean manufacturing can be adapted to support any industry.

Simply put when it comes to lean less is best. Core to this philosophy involves the principle that expenditure of resources for any goal other than the creation of value for the end customer is wasteful and therefore should be a. Read more on Lean Management and the Lean Principles.

This concept grew out of two things. If theres not you can use the data from your test to help you pivot and change your business plan. The Lean methodology aims to reduce wasteful activities as much as possible.

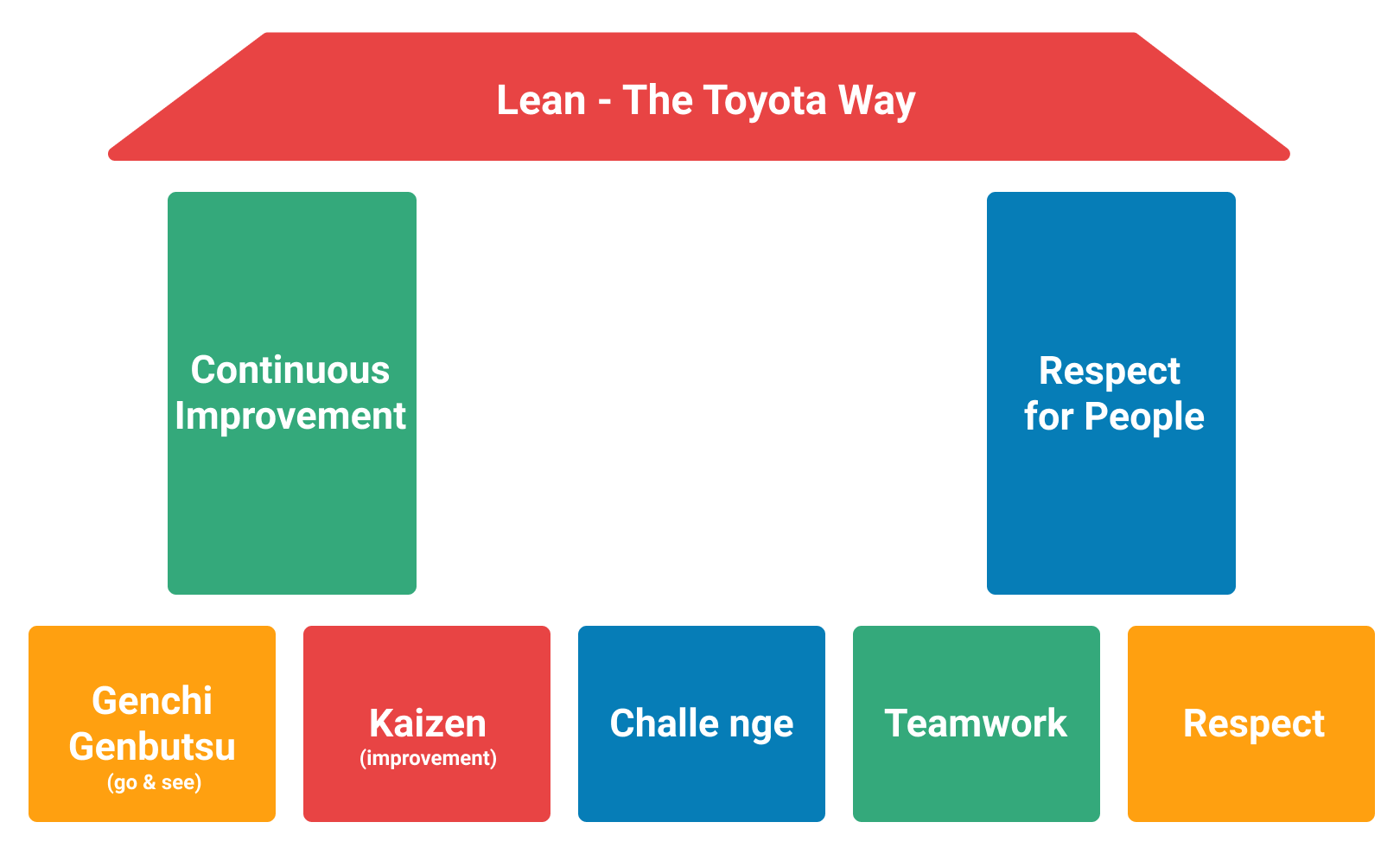

Lean methodology maintains its hold in manufacturing and continues to expand into new applications that include knowledge work helping businesses eliminate waste improve processes and boost innovation in work thats not limited to production in manufacturing. The benefits of lean manufacturing are vast. Lean is founded on two pillars.

Through Lean it is possible to have better products made in a shorter time and at lower costs. Lean methodology is a quality improvement strategy with the overarching goal of using less to do more. Two important books The Machine That Changed the.

Lean Six Sigma is a process improvement methodology designed to eliminate problems remove waste and inefficiency and improve working conditions to provide a better response to customers needs. A lean process works to improve business efficiencies while reducing wasteful practices that tarnish business results. What is the Lean Methodology.

Lean methodology is very effective at eliminating and reducing waste. Lean manufacturing or lean production is a production method derived from Toyotas 1930 operating model The Toyota Way Toyota Production System TPSThe term Lean was coined in 1988 by John Krafcik and defined in 1996 by James Womack and Daniel Jones to consist of five key principles. Lean is an improvement and problem solving methodology that strives to reduce or eliminate activities that dont add value to the customer.

But what does LEAN really mean. Reduce waste improve process improve quality increase efficiency at all levels of an organization. It is based on two guiding tenets continuous improvement and respect for people.

In short Lean methodology is a way of optimizing the people resources effort and energy of your organization toward creating value for the customer. Lean is a philosophical way of working which emphasizes the removal of waste within a process. Lean methodology is simply a way of optimizing every aspect of your business including the people materials and.

They have benefited through increased productivity elimination of waste and improved quality resulting in. LEAN is a powerful methodology that allows teams to deliver value to customers while minimizing waste. Lean methodology is a way of optimizing the people resources effort and energy of your organization toward creating value for the customer.

The Lean methodology aims to reduce or eliminate all unprofitable activities of a company. What are its principles and core concepts. So if you opt for the Lean methodology do.

The build-measure-learn loop is a way for you to see if theres customer interest in your idea. The lean startup methodology is a way for you to use a feedback loop to test your business idea. Its applied across industries with its origins in manufacturing but the core goals of lean methodology are the same.

This method has its limits but if properly applied it makes it possible to reconcile productivity and quality of work.