Share your videos with friends family and the world. Lean Staffing Solutions is an employment agency providing staffing services for various companies.

Lean Staffing Solutions Offers Full Stack Of Tech Sales And Marketing Services Freightwaves

Lean Staffing Solutions Offers Full Stack Of Tech Sales And Marketing Services Freightwaves

Lean Staffing Solutions offers full stack of tech sales and marketing services.

Lean staffing solutions. Our main market is the Logistics and Transportation. We provide the perfect combination to help you succeed. Brian Straight managing editor Modern Shipper Thursday October 8 2020.

Lean Staffing Solutions Colombia Barranquilla Colombia. The service allows its customers to have. Employees learn - how to track and trace make live check calls request PODs basic US geography time zones terminology for trailer equipment how many pallets fit in a truck.

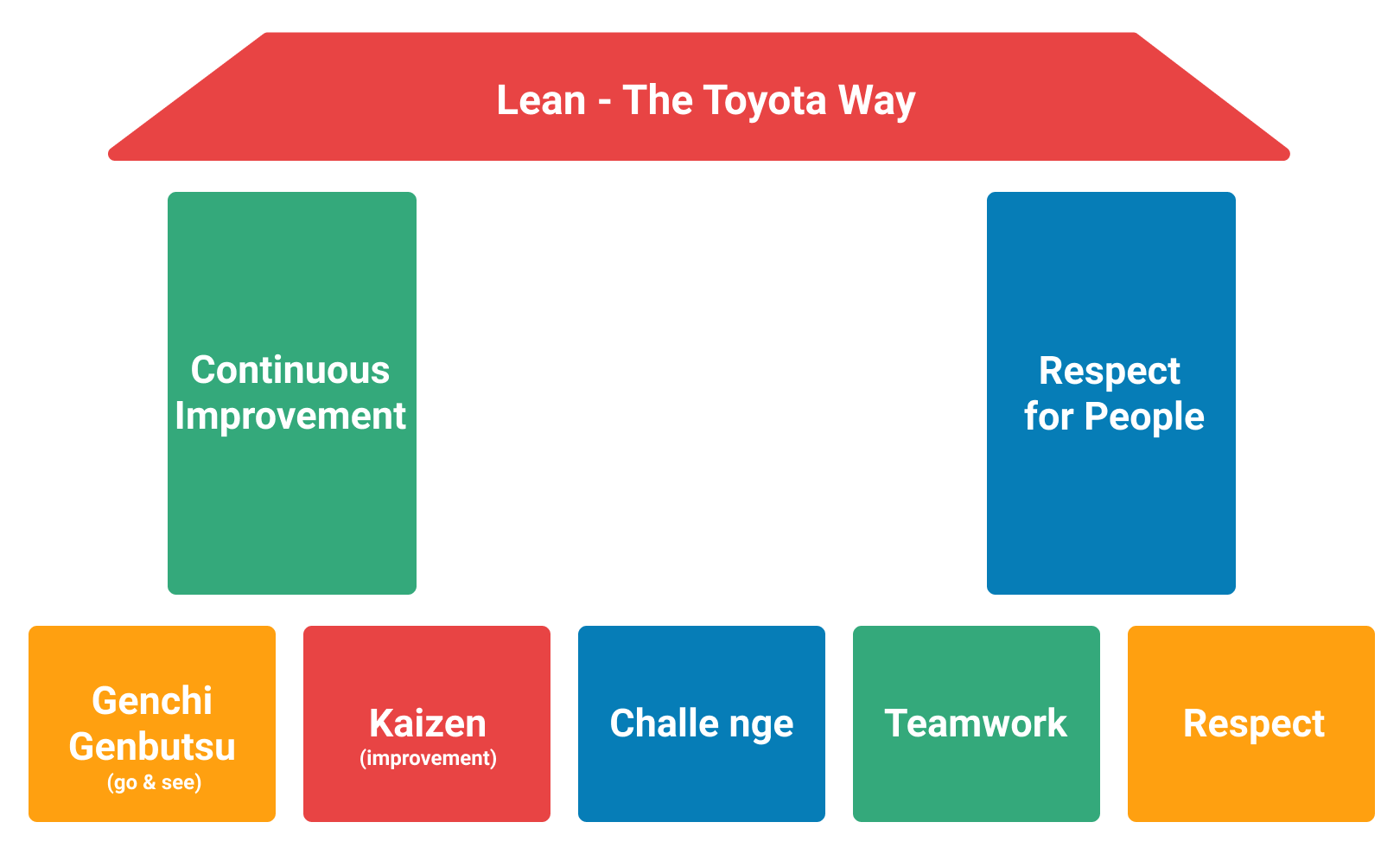

Lean Sales is a division of Lean Staffing Solutions a pioneer in Nearshore staffing services. At Lean Staffing we know that finding the right people can be challenging especially when it comes to entry-level positions. A quality-oriented company culture values the characteristics of quality that the system measures and strives for continuous improvement.

2021 Lean Solutions Group. With our screening process and training programs the dream team will be a reality for your business in no time. We provide highly qualified bilingual employees so you can get back to running your business.

The agency main market is the Logistics and Transportation Industry. Lean Staffing Solutions LSS is a company dedicated in providing staffing services for various companies in the United States and Canada. Lean Solutions Group is more than just a place where you will work we are a community a family.

Follow us in Our social media. We Are Experts on Staffing Solutions. Lean Staffing Solutions Lean Staffing Solutions LSS a staffing firm offering nearshored solutions in Colombia focused on transportation and logistics announced Tuesday that it had raised a 425 million growth equity minority investment from FTV Capital.

Lean Staffing Solutions LSS a leading provider of nearshore expert outsourced solutions for transportation and logistics companies in the United States today announced a 425 million. As we work together we strive to create an environment where you will learn express yourselves and youll get the opportunity to show your capabilities and talent. Lean Staffing is a Near Shore Services Provider located in.

Supplies staffing options for logistics companies in the United States. Contact us and tell. Maintaining a team of reliable entry-level employees is a challenge in itself.

Over the past two years Lean Staffing Solutions has diversified its offerings beyond back-office logistics employees to include revenue-generating positions sales marketing and software development. 3885 likes 56 talking about this. Lean Solutions Group is Right for You.

At Lean Solutions Group we are eager to start working with you and helping your company reach its operational goals increase revenue and enhance your workforce with an extension of your team in South America Colombia. Lean Staffing does an initial transportation workshop. New tech marketing and sales solutions augment Leans original back-office staffing service.

AscendTMS And Lean Staffing Solutions Partner To Provide Low-Cost Staffing Services In AscendTMS InMotion Global Inc. Logistics Solutions At Lean Staffing we create the perfect extension of your team made up of qualified bilingual professionals ready to fulfill any of your companys needs With the combination of our proven success formula and the right talent right culture and right price we know we will fulfill your expectations and help your company grow without limits. Our sole focus is to accelerate your revenue growth by providing best-in-class sales solutions.

Lean Staffing Solutions offers full stack of tech sales and marketing services. To ensure customer satisfaction standardize processes and improve quality Lean Staffing Solutions has now opened the Quality Department. Help us help you.

Based companies the infrastructure support and staff near shore by opening a satellite workplace within their facilities. All rights reserved. Announced today that AscendTMS the worlds number one rated transportation management software TMS has partnered with the largest nearshore logistics staffing company Lean Staffing Solutions to offer bundled TMS.