In the early stages of lean there should be at least 80 doing and 20 training. The Toyota Production system is a major precursor of Lean Manufacturing.

Toyota Production System Lean Process Consultants

Delivering value to the customer and minimizing waste and Lean project managers strive to deliver.

Toyota lean process. A production system based on the philosophy of achieving the complete elimination of all waste in pursuit of the most efficient methods. The elements of Lean Manufacturing as first invented by Toyota. The philosophy is to work intelligently and eliminate waste so that only minimal inventory is needed.

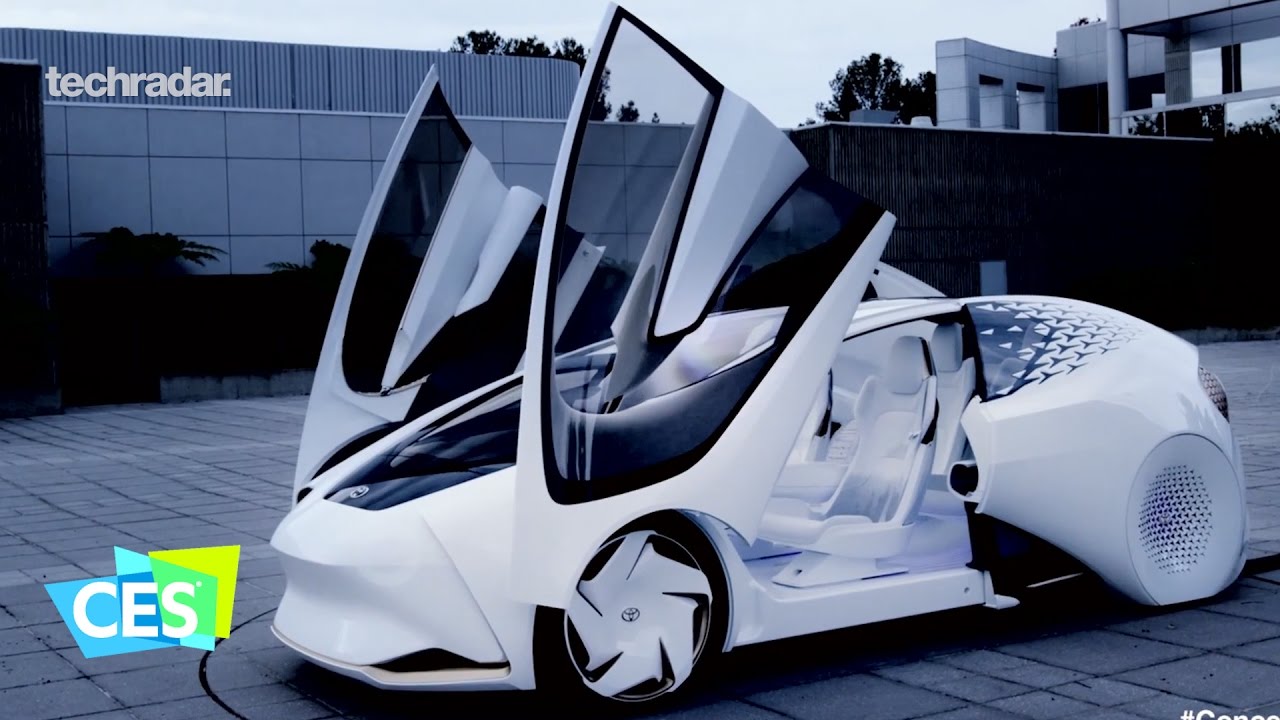

It is regarded as the benchmark for manufacturing best practice. Empowering workers transferring maximum power and tasks to those who do the job. The way we make vehicles is defined by the Toyota Production System TPS.

Owning the entire process the supply chain. The Toyota Production System TPS follows the philosophy of making only what is needed when it is needed and in the amount needed TPS is based on two concepts. Toyota concluded that by right-sizing machines for the actual volume needed introducing self-monitoring machines to ensure quality lining the machines up in process sequence pioneering quick setups so each machine could make small volumes of many part numbers and having each process step notify the previous step of its current needs for materials it would be possible to obtain.

It provides a high level overview of the most basic tools used by Toyota and lean manufacturing. This presentation is for the students of Bainbridge Graduate Institute in the Sustainable Operations Course MGT-564. The best training is training followed by immediate doing or doing followed by immediate training Use experts for getting quick results.

Maximise Productivity and Efficiency. Owning the entire process the distribution and customer obsession. This increases cash flow and reduces physical space needs and makes it easier to deliver the required results smoothly through internal processes.

Our highly acclaimed and successful Toyota Production System TPS is admired and copied throughout the world. The Toyota way is about learning by doing. Lean project management is the application of Lean principles perfected by Toyota to the discipline of project management.

Founded on the conceptual pillars of Just-in-time and Jidoka or Automation with a Human Touch the system was first built off the approach created by the founder of Toyota Sakichi Toyoda and his son Kiichiro Toyoda. Toyota lean manufacturing process has been a source of inspiration for many businesses for years. The presentation is 33 minutes long.

The two fundamental focuses are. This is a SlideCast which means there is an AUDIO TRACK so please turn on your speakers. Jidoka or intelligent automation meaning that when a problem occurs the process stops immediately to prevent any defective products from being produced.

The way they strive to increase productivity and efficiency with the aim of continuously improving business and manufacturing processes in an endless cycle. Toyota Motor Corporations vehicle production system is a way of making things that is sometimes referred to as a lean manufacturing system or a Just-in-Time JIT system and has come to be well known and. It is an original manufacturing philosophy that aims to eliminate waste and achieve the best possible efficiency what is often called a lean or just-in-time system.

Nampachi Hayashi claims that TPS should have been called Toyota Process Development System Most uses of the word Lean are actually referring to TPS. In these difficult and highly competitive times a lean approach has never been more important.